Background to Industry standards

Why is scania changing?

Scania is taking a big step in its digitalization journey by transitioning to industry standards. This means that Scania is updating its IT landscape and general ways of working to enable strategic growth ambitions – to make the organization future proof and make Scania a more attractive partner to work with. These changes will make it easier to meet the demands of the future, serving the customers of today with better prediction in delivery.

What is in it for suppliers?

Scania aspires to develop a modern supply chain collaboration hub in close partnership with suppliers. Thus, a global standardized way of working that resembles those of suppliers other clients. This is based on OEM & industry best practices, to reduce complexity and enable the introduction of a user-friendly and future-proof system landscape. This will lead to greater data visibility and transparency, that will improve decision making and predictability throughout the partnership. The supplier experience will be optimized, and insights in the traceability of deliveries throughout Scania supply chain will be improved.

Implications for suppliers

Scania is implementing a new ERP (Enterprise Resource Planning) system and global standardized way of working as the foundation for administrative and transactional processes within Industrial Operations. When launching the new IT landscape, Scania is required to make changes to the current EDI setup and label formats impacting suppliers.

Overview of key changes

- Updates to EDI landscape

New and improved EDI messages (incl. Delivery schedule, Advanced Shipping Notice (ASN), and Invoice). The new EDI message version specifications is communicated in the technical specifications and logistics manual. This will require IT changes on your end.

- Updates to transport labels

Implementing Global Transport Label (GTL); including new format with unique identifier number for outer and inner packaging level. This number needs to be applied to the ASN and the labels of all goods that are sent to Scania.

- Introduction of scheduling agreement

A new supplier number and part numbers are introduced. The agreement consists of a list of prices and parts and is intended as an extension to the current contract. The current contract still remains the valid legal document

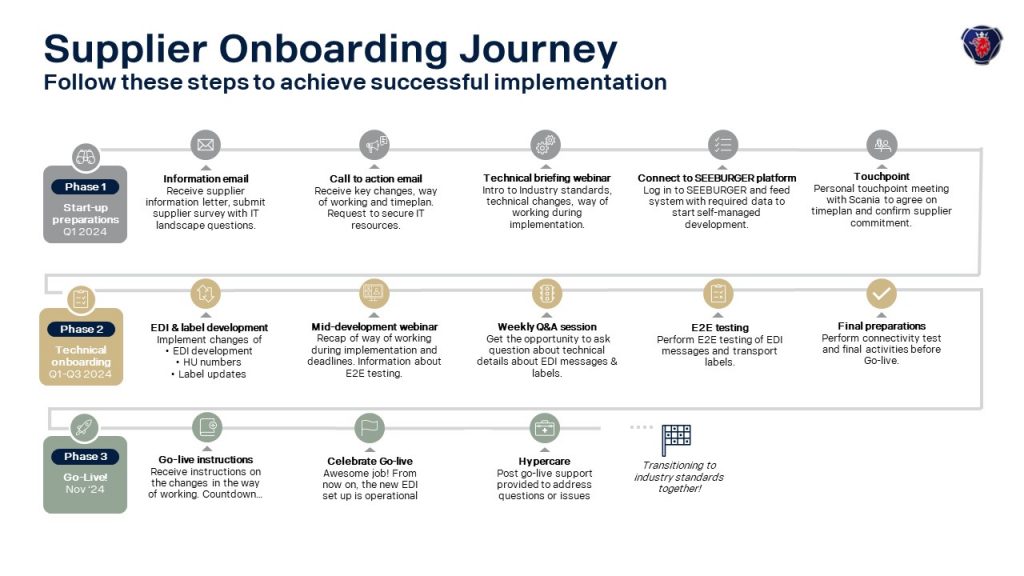

Onboarding journey and timeline

A implementation plan is outlined for you as a supplier, and you will be supported through this journey by our Supplier Readiness Team. You as a supplier is expected to comply and make sure to follow timelines and set deadlines.

Industry standards outlook

This implementation will continue in the upcoming years and all automotive parts suppliers working with Scania will eventually be impacted. Please note that you will be notified by Scania once you are in scope for the transition to industry standards.

The first Industry Standards releases took place in the Battery Factory in Södertälje in 2023. The next phase takes place in 2024 and applies for all automotive parts deliveries for serial production to Scania via Hasselt Logistic Hub Central Europe, Logistic Center & Consolidation Point.

| Supplier Information Letter | 14 Feb, 2024 |

| Vision and Mission | 14 Feb, 2024 |

| Supplier Onboarding Journey | 21 Feb, 2024 |